UC Food Blog

You should taste it fresh

Question: What exotic fruit has been named as a flavor in Starburst candy, Ice Breakers gum, SoBe beverages, Vitamin Water drinks, Bacardi rum and even Axe body spray?

Answer: Dragon fruit. (Hylocereus spp.)

So while many of us may have tasted products that flaunt its name, have you ever sunk your teeth into a fresh dragon fruit?

If you want to try one, you may be in luck because now is the peak harvest season in Southern California for this subtropical cactus fruit with the fire-breathing name — also known as pitahaya. And it just so happens that growing and eating fresh dragon fruit is what Ramiro Lobo, UC Cooperative Extension farm advisor for San Diego County and the Small Farm Program, is most interested in.

Lobo says he’s known about pitahaya since he was a kid, but his professional interest was rekindled when the enthusiasm of the Rare Fruit Growers group intersected with an ongoing quest to find crops that are more water-efficient for the region.

“Wherever you can grow Hass avocados, you can grow dragon fruit,” he said. “And it uses less water than avocados or any other orchard crop that we grow in San Diego.”

Though this used to be a fruit found only rarely in specialty stores, Lobo says that is changing.

“We’ve seen the market expanding. We’re seeing it in high-end restaurants in Los Angeles and Las Vegas,” he said. “Supply is very sketchy right now, but growers who are selling direct at farmers markets are getting $7-8 per pound. Hardly any other fruit today is bringing that kind of money.”

One other clue that the U.S. market for this “artichoke from Mars” (as one LA Times writer described it) is expanding? Imports of the fruit have been growing from Vietnam, with perhaps 600 tons imported in 2010. And the USDA is currently working through the processes that could allow imports from Mexico, Thailand and Central America too.

While Lobo doesn’t sound too worried about competing with imported dragon fruit, he does hope your first taste of fresh dragon fruit is indeed very fresh.

“We cannot compete with Vietnam fruit for price, but we can definitely compete for quality,” he said. “The challenge is that a lot of people are exposed to dragon fruit, but the fruit quality is lousy. It’s a very sensitive fruit, so if you put it in a container and send it across the ocean for 10 days, it’s not going to be as good. But people who get exposed to a good variety keep buying it.”

In California, it is estimated that about 200 acres are planted in pitahaya, with anywhere from 400 to 1,000 acres planted nationwide.

Lobo oversees approximately 500 dragon fruit plants at the UC South Coast Research and Extension Center in Irvine. He is currently working to set up an irrigation trial for pitahaya, to better evaluate its water requirements. He is also working to test out different trellis systems, comparing hedge versus orchard systems for this fruiting cactus.

The UC South Coast Research and Extension Center is also where the pitahaya field day was held recently. Lobo said questions from the day’s 100 or so participants sounded like more growers are getting serious about growing pitahaya commercially, with more technical questions and an interest in disease, rodent and pest management.

“The bar has been raised, and [some of those questions] even put us in a bind because without the research, it is kind of hard to answer them,” he said.

In the meantime, Californians and marketing companies will probably continue to find new secondary uses for this fruit’s juice, pulp and name: Lobo says he’s seen wines made with dragon fruit and organic yarn dyed naturally with that fiery pink flesh.

Pitahayas, as packed at a small farm in San Diego. (Photo by Shermain Hardesty)

At UC South Coast Research and Extension Center, the dragon fruit plants are currently in an orchard system, though new trellis trials will soon be under way. (Photo by Shermain Hardesty)

Pitahaya blooms at UC South Coast Research and Extension Center. (Photo by Shermain Hardesty)

Colors of ripe pitahaya flesh can vary between red, fuschia, pink and white.

Irvine Field Station white flesh pitahaya

Fresh picked in the Delta

Last Sunday morning, I drove about 10 minutes out of Sacramento to visit one of my favorite farms and pick some peas. (beans actually, but who cares...) R. Kelley Farm, on state Highway 160 just south of Freeport, is an international gathering-place for lovers of fresh black eye peas, crowder peas, other peas, beans and the fresh vegetables that go well with them. Picking your own gives you the best prices, but ready-picked bins of eggplant, tomatoes, melons, peppers and, of course, beans, fill the airy farm stand. When I arrived, the parking lot was full and the place was jumping.

By 11 o'clock in the morning, Susila Prasab and her family had already picked about a hundred pounds of fresh crowder peas. They climbed off the tractor-pulled wagon that brought them back from the picking field with about five big mesh bags full, ready to get them weighed and pay the Kelley Farm 78 cents a pound. The fresh beans (crowder peas, like black eye peas, are really beans) would soon be shelled, cleaned, blanched and frozen, ready to use as the main ingredient for several months' Indian curry meals. Prasab told me the quick version of her curry recipe.

Quick Indian curry: Like many recipes, it starts with onion, garlic and chili sautéed in a pan with a little oil. Add curry powder and marsala. Wash the shelled fresh beans and add them to the pot. You can add potato or eggplant or tomato or cilantro, or all of them if you want. Add a little water, cook slowly, and serve with rice.

The Prasab family, like most of the others picking fresh black-eye peas, crowder peas and purple beans that morning, were originally from Fiji. The Fijians came from homes in Sacramento, Elk Grove, and even Hayward to pick at Ron and Ella Kelley's 40-acre farm. The farm reminds many of them of Fiji, where they often had small farms or backyard plots, growing their own crowder peas and other vegetables.

Nath Sam, from Fiji by way of Elk Grove, stopped picking purple beans for a few minutes to explain the best way to keep the beans for three seasons in the freezer:

Prepping fresh beans for the freezer: Shell the beans. Boil a lot of water. Throw the beans in for just a few seconds. Take them out quickly and cool them with ice. When they are room temperature, put them in a ziploc bag and seal it tightly. Put bags in the freezer.

R. Kelley Farms is open for picking or buying ready-picked fresh vegetables Wednesday through Sunday, July through October, from 8 a.m. to 6 p.m. On the day I visited, Lynette Hall, the Kelleys' daughter, was at the cash register. Hall told me she was surprised, at first, to learn that so many people all over the world have recipes for black eye peas, crowder peas, okra, and other ingredients for African-American soul-food specialties. Hall was more familiar with her mother's southern-style beans and offered her own recipes for stuffed zuchini or bell peppers and for Sucatosh.

Ella Kelley's fresh beans with turkey: Cook some smoked turkey (necks or legs or whatever you have) until the meat comes off the bone with a fork. Saute onion, garlic and bell pepper. Add the turkey and turkey juice to the mixture. Throw in any kind of fresh shelled beans, black eye, crowder or purple. Cook for about 20 minutes. Serve over rice.

Lynette Hall's stuffed zucchini: Cut a big zucchini squash in half. Scrape out the seeds. Saute onions, garlic and bell peppers with some sausage and hamburger meat. Add some uncooked saffron yellow rice and a couple of eggs to bind everything together. Fill the hollowed-out squash halves with the mixture. Top with a layer of mozzarella cheese and some bread crumbs. Bake at 375 to 400 degrees for about 45 minutes.

Lynette Hall's succotash: Start with meat in a frying pan. When the meat is tender, add the vegetables, using any combination of onions, garlic, okra, peppers, squash, eggplant, tomatoes, fresh beans and corn. Cut the corn fresh off the cob, cutting the kernels half-way through. Then scrape the corn milk off the cob to get the juice. The corn juice adds to the tomato juice to flavor this dish. Season to taste. Serve over rice.

More black eye pea information and recipes.

When I paid for my beans at R. Kelley Farm, I picked up a flier on the counter telling me about fresh pears at Maggi's Farm, just next door. So of course I had to stop by Maggi's for some pears on my way home. But that's another story.

For best results, kids and parents both need nutrition education

UC Cooperative Extension has found a health and fitness formula that works. Combining fun exercise and nutrition classes for kids with special sessions for parents melts away pounds and inches.

The concept was proven successful at a day camp offered by the City of Fresno Parks and Recreation and Fresno County UC Cooperative Extension this summer. About 90 overweight or obese children were recruited to participate in the six-week program at Ted C. Wills Community Center and Holmes Playground. Their parents attended two mandatory evening meetings a week.

In all, the campers lost 241 pounds. More significantly, a combined 253 centimeters was erased from the children’s waistlines. The number of pounds lost is skewed by the fact that some of the children grew taller during the summer. The number of waistline inches lost reflects improved muscle tone.

“Without involving parents, it is very difficult for children to make changes in food choices,” said Sara Bosse, the nutrition education manager for UC Cooperative Extension in Fresno County. “Parents are the ones doing the shopping and preparing meals. If the children don’t have the opportunity to practice what they learned at home, their efforts are going to be sabotaged.”

The children gathered five days a week to learn about and taste fruits and vegetables prepared in several different ways. The recipes were shared with parents at the evening meetings, where they also had the opportunity to try some prepared dishes.

“With exposure to the food in different manners, they gain acceptance to fruits and vegetables that they didn’t like before,” Bosse said.

The children also participated in physical activities and maintained journals in which they chronicled their evolving tastes for healthy food.

Previous research has shown that children typically gain more weight in the summertime than they do during the school year.

“If kids aren’t involved in a program, they may be just sitting at home and getting bored and eating more,” Bosse said.

This year’s project shows how that trend can be reversed.

View a video of a healthy fitness camp parent meeting featuring UC Cooperative Extension nutrition program coordinator Angelita Zaragoza below.

Read a transcript of the video.

Following is the recipe:

Vegetable and tofu stirfry

Ingredients:

1 tablespoon vegetable oil

4 ounces firm tofu cut into small cubes

1 14 ounce can diced tomatoes

5 cuts cut up vegetables, fresh or frozen, such as broccoli, bell peppers, cauliflower, sugar snap peas, carrots, etc.

2 cups broth

2 tablespoons corn starch

1 teaspoon garlic powder

A pinch of pepper

2 tablespoons soy sauce

6 cups cooked brown rice

Instructions:

Sauté tofu in oil until lightly browned. Add the rest of the ingredients, except the rice. Bring to a boil, then simmer for 10 minutes or until the vegetables are tender. Serve on cooked brown rice.

Angelita

Pistachio harvest: Wait, split, GO!

“Pistachio is a funny kind of nut,” says UC pomologist Louise Ferguson. With other nuts, the shell grows and hardens as the kernel develops, whereas pistachio grows its shell first, hardens it, and then plumps up a kernel inside. As early perhaps as Labor Day, when growers are always hopeful the harvest can begin, it will be seen whether the nuts in the millions of trees in California orchards have formed well.

Tension is rising. In these last hot days of August, as the nuts reach maturity, the shells must split. If too many of them don’t, the harvest will be much less profitable, because it’s hard to make a natural-looking split in a pistachio shell with a machine, and unsplit pistachios bring a lower return. Growers are watching the split percentages carefully; wait too long for the highest number and navel orange worms have a larger window of opportunity to lay eggs along the sutures.

Pistachio orchards are harvested mechanically, and the machines are generally owned by contractors, though a large farm may have its own. As soon as the first machine enters the first orchard — the greatest acreage is on the west side of the San Joaquin Valley, around Bakersfield — a race begins.

“It’s chaotic,” says Ferguson. For more than 15 hours every day, beginning before dawn and finishing at dark, the harvesters speed through tunnels of dust and noise up and down orchard rows, followed by bank-out wagons that must get the nuts to the processing plant for drying before the day is out. Each wagon holds 55,000 pounds of pistachios. Left too long in the heat, under the weight of such a load, the pink hulls (each nutshell is within a hull) degrade and stain the shells a darker shade, which lowers the nuts’ value. The California pistachio industry prides itself on producing a large, naturally split, light shelled nut with no artificial splitting or bleaching.

The race gets more fraught each year because contractors have significantly more and more acreage to harvest within the six-week harvest season. Ferguson calls pistachio the “single most successful plant introduction in the 20th century.” The California crop has grown from zero to approaching a quarter million acres in 40 years.

Ferguson knows all about the harvesters, because they are no longer working well as the trees age. It’s her job to develop a harvester that does. The standard pistachio harvester is a trunk shaker: it has two units, one each side of the tree row, which travel together, lock onto a tree trunk, and shake it for 4 to 8 seconds so that nuts fall into the catch frame — resembling huge wing structures — that the units place beneath the tree canopy. The catch frame flicks the nuts into the conveyor belt at the base of the frame, which takes them to the back of the harvester, where they are conveyed through an air leg to remove debris out to the wagon while the harvester keeps moving from tree to tree.

Mature trees have thicker trunks that don’t shake as well, and the trees are now so large, “some nuts can go flying over the catch frame,” says Ferguson. She has trials under way with a direct-canopy-contact harvester. “It’s like a big hairbrush,” she says, that ruffles the tree canopy to get the nuts out of the tree.

Her colleagues at UC Davis are breeding varieties with a more reliable split and a very early or very late harvest date to spread out the season. Meanwhile, the chaos goes on. This year, because of the cool spring, Ferguson suspects the nuts will split over an extended time period, so growers may well decide to harvest once, then a few weeks later get the harvesters back for a second time.

See a tree shaker harvesting pistachio nuts below. (Video provided by Coe Orchard Equipment.)

Pistachio harvest

From 'backyard to belly'

So you may have heard of ”farm to fork” or “farm to table”? Well, I like to think even more locally than that. I think in terms of “backyard to belly” . . . food so fresh you can eat it while standing in the garden without cooking it or with a little more effort, carrying a basket of fresh tomatoes, zucchini, peppers, eggplants, peaches, corn and beans into the kitchen to create wonderful meals for your family.

I have a few tips on getting quality food from your harvest. So often we lose a lot of our homegrown produce because we don’t harvest at the right time. It is important to harvest at the peak of perfection - not before and not after. My worst food experiences from my garden have come from waiting too long to harvest. The corn gets starchy (and the corn earworms get more of the kernels than I do), the beans get tough, the melons, when overripe, are not even worth cutting open and peaches will not hold up well when they are cooked or canned. To be a good gardener and a good chef of ”backyard to belly” foods, you really have to stay on top of the harvest and not let it get ahead of you. I know that if you work full time, you just may not have the time to harvest when you need to, but if you don’t take the time, then you have pretty much wasted your time and garden resources.

One thing that can help is to invest in a separate cold storage system, I call it my “fruit fridge” (just a used refrigerator in the garage), in which you can store your harvested produce until you can process it either by cooking, or for longer term storage canning, freezing or drying. Your regular household refrigerator will work just fine but often there is too much produce and you won’t have enough room. Refrigeration will help to keep the produce fresh longer and allow you a little more time to process. For example, I have too much corn ready at one time. Corn is best eaten within a few hours after harvest since the conversion to starch occurs quickly. While it would be fun to have a corn feed or share with all my neighbors, I really would like to store some for the winter. I harvest my corn so that it is just mature but not too mature. Typically, the ears will be filled with kernels and the tips of the silks will begin to dry out. The “milk” from the kernels should be clear and not white. After harvest, I quickly move the ears to the refrigerator since that slows the conversion rate of sugar to starch. When I have time within the next day or so, I will prep them for freezing. The sooner you can process the corn, the better the quality will be.

Peaches are another crop that tends to be ready at one time. One thing I do is write the approximate harvest date in my calendar for the next year so I won’t schedule a vacation during the harvest period. Second, peaches are best harvested for longer term storage (canning, freezing and drying), when they are fully ripe but still firm. You can then leave them on the counter until they are at the stage you prefer them at for fresh eating. If you intend to can, freeze or dry the fruit, it is best to process them shortly after harvest. If you have to wait to process, then store them in your fruit fridge until you are ready, but you should do it within a few days.

If you want more information on proper harvesting and storage of home garden vegetables and fruits, visit these pages on The California Garden Web and The California Backyard Orchard. If you are new to preserving foods, The National Center on Food Preservation has free guidelines for you.

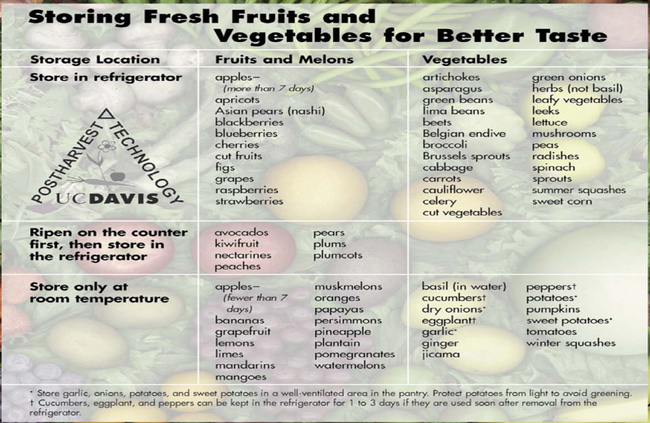

You may also want to visit the Postharvest Technology Center webpage for more information on storing fresh fruits and vegetables for better taste.